Magnetic Hysteresis

The phenomenon of flux density B lagging behind the magnetizing force H in a magnetic material is known as Magnetic Hysteresis. The word Hysteresis is derived from the Greek word Hysterein means to lag behind. In other words, when the magnetic material is magnetized first in one direction and then in the other direction, completing one cycle of magnetization, it is found that the flux density B lags behind the applied magnetization force H.

There are various types of magnetic materials such as paramagnetic, diamagnetic, ferromagnetic, ferromagnetic and antiferromagnetic materials. Ferromagnetic materials are mainly responsible for the generation of the hysteresis loop.

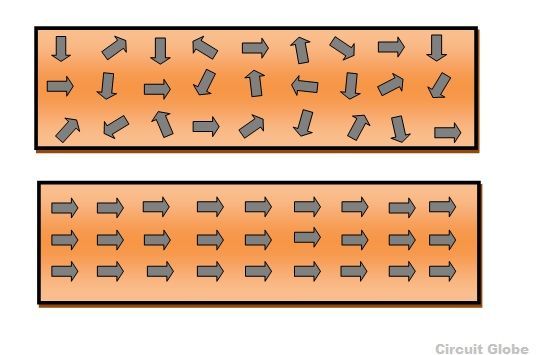

When the magnetic field in not applied the ferromagnetic material behaves like a paramagnetic material. This means that at the initial stage the dipole of the ferromagnetic material is not aligned, they are randomly placed. As soon as the magnetic field is applied to the ferromagnetic material, its dipole moments align themselves in one particular direction as shown in the above figure, resulting in a much stronger magnetic field.

When the magnetic field in not applied the ferromagnetic material behaves like a paramagnetic material. This means that at the initial stage the dipole of the ferromagnetic material is not aligned, they are randomly placed. As soon as the magnetic field is applied to the ferromagnetic material, its dipole moments align themselves in one particular direction as shown in the above figure, resulting in a much stronger magnetic field.

Contents:

- Residual Magnetism

- Coercive Force

- Soft Magnetic Material

- Hard Magnetic Material

- Applications of Magnetic Hysteresis

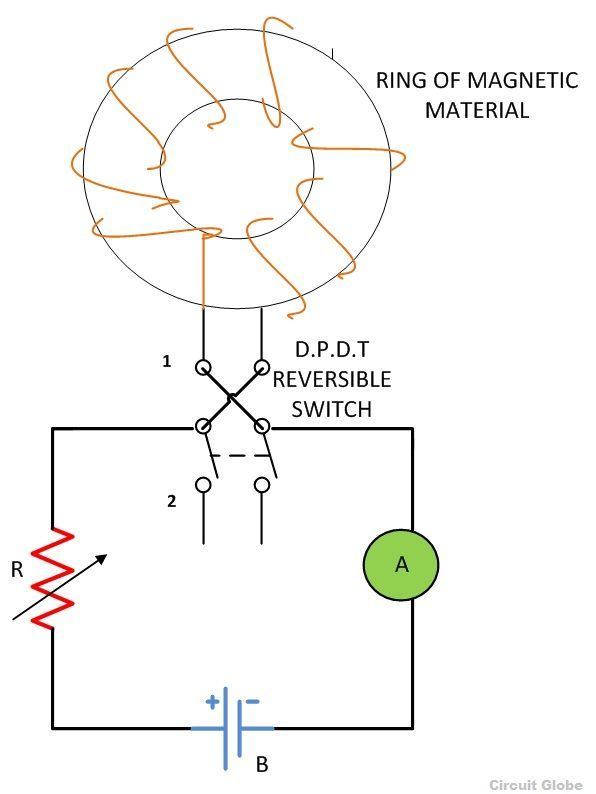

For understanding the phenomenon of the magnetic hysteresis, consider a ring of magnetic material wound uniformly with solenoid. The solenoid is connected to a DC source through a Double pole double throw (D.P.D.T) reversible switch as shown in the figure below

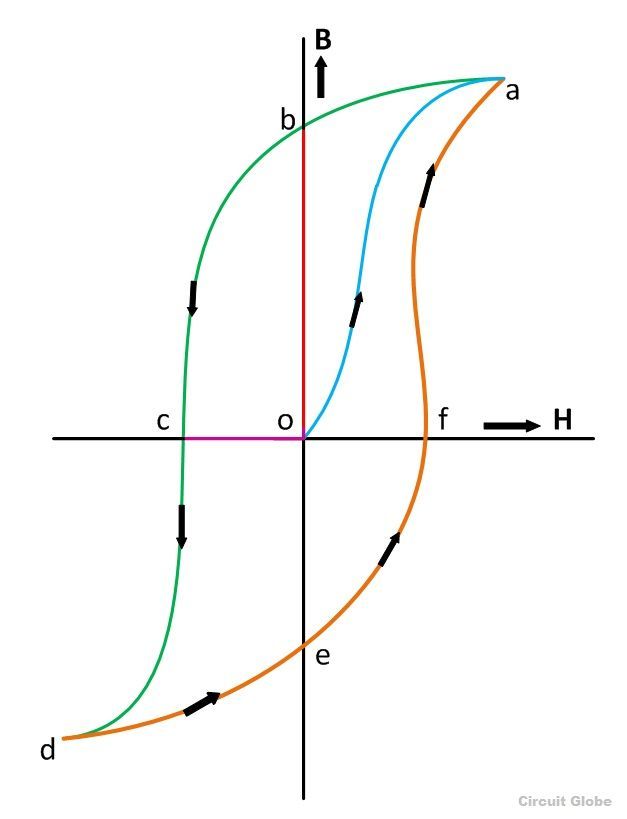

Initially, the switch is in position 1. By decreasing the value of R the value of the current in the solenoid increases gradually resulting in a gradual increase in field intensity H, the flux density also increases till it reaches the saturation point a and the curve obtained is oa. Saturation occurs when on increasing the current the dipole moment or the molecules of the magnet material align itself in one direction.

Now by decreasing the current in the solenoid to zero the magnetizing force is gradually reduced to zero, but the value of flux density will not be zero as it still has the value ob when H=0, so the curve obtained is ab as shown in the figure below.This value ob of flux density is because of the residual magnetism.

Residual Magnetism

The value of the flux density ob retained by the magnetic material is called residual magnetism, and the power of retaining it is known as Retentivity of the material.

Now to demagnetize the magnetic ring, the position of the D.P.D.T reversible switch is changed to position 2 and thus, the direction of flow of the current in the solenoid is reversed resulting in reverse magnetizing force H. When H is increased in reverse direction, the flux density starts decreasing and becomes zero (B=0) and the curve shown above follows the path bc. The residual magnetism of the material is removed by applying the magnetizing force known as Coercive force in the opposite direction.

Coercive Force

The value of the magnetizing force oc required to wipe out the residual magnetism ob is called Coercive force shown by pink color in the hysteresis curve shown above.

Now to complete the hysteresis loop the magnetizing force H is further increased in the reverse direction till it reaches the saturation point d but in the negative direction, the curve traces the path cd. The value of H is reduced to zero H=0 and the curve obtains the path de, where oe is residual magnetism when the curve is in the negative direction.

The position of the switch is changed to 1 again from the position 2 and the current in the solenoid is again increased as done in the magnetization process and due to this H is increased in the positive direction tracing the path as efa, and finally the hysteresis loop is complete. In the curve again of is the magnetizing force, also known as the Coercive force required to remove the residual magnetism oe.

Here the total Coercive force required to wipe off the residual magnetism in one complete cycle is denoted by cf. From the above discussion, it is clear that the flux density B always lags behind the magnetizing force H. Hence the loop ‘abcdefa’ is called the Magnetic Hysteresis loop or Hysteresis Curve.

Magnetic hysteresis results in the dissipation of wasted energy in the form of heat. The energy wasted is proportional to the area of the magnetic hysteresis loop. Mainly there are two types of magnetic material, soft magnetic material and hard magnetic material.

Soft magnetic material

Soft magnetic material

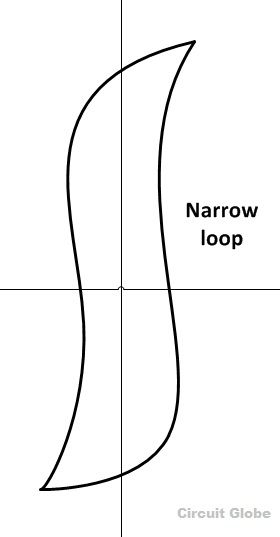

The soft magnetic material has a narrow magnetic hysteresis loop as shown in the figure below which has a small amount of dissipated energy. They are made up of material like iron, silicon steel, etc.

- It is used in the devices that require alternating magnetic field.

- It has low coercivity

- Low magnetization

- Low retentivity

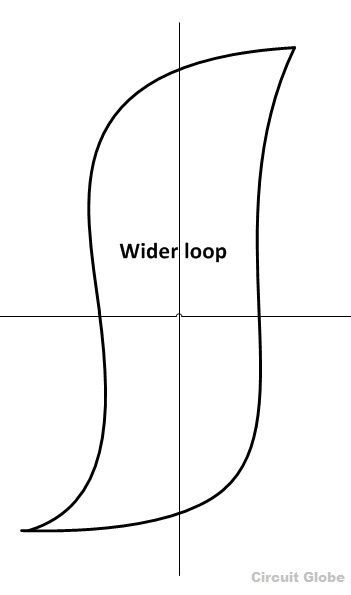

The Hard magnetic material has a wider hysteresis loop as shown in the figure below and results in a large amount of energy dissipation and the demagnitisation process is more difficult to achieve.

- It has high retentivity

- High coercivity

- High saturation

- Magnetic material having a wider hysteresis loop is used in the devices like magnetic tape, hard disk, credit cards, audio recordings as its memory is not easily erased.

- Magnetic materials having a narrow hysteresis loop are used as electromagnets, solenoid, transformers and relays which require minimum energy dissipation.

No comments:

Post a Comment