Advantages of 3 Phase Over Single Phase System

The three-phase system has three live conductors which supply the 440V to the large consumers. While the single phase system has one live conductor which is used for domestic purposes. The following are the main advantages of 3 Phase system over Single Phase system.

- Higher Rating

The rating, i.e. the output of a three-phase machine is nearly 1.5 times the rating (output) of a single phase machine of the same size.

- Constant Power

In single phase circuits, the power delivered is pulsating. Even when the voltage and current are in phase, the power is zero twice in each cycle. Whereas, in the polyphase system, the power delivered is almost constant when the loads are in balanced condition.

- Power Transmission Economics

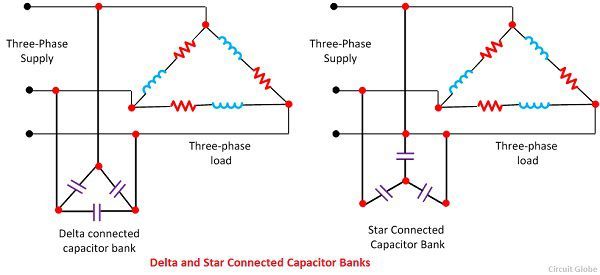

The three phase system requires only 75% of the weight of conducting material of that required by single phase system to transmit the same amount of power over a fixed distance at a given voltage.

- Superiority of 3 Phase Induction Motors

The three Phase induction motors have a widespread field of applications in the industries because of the following advantages are given below.

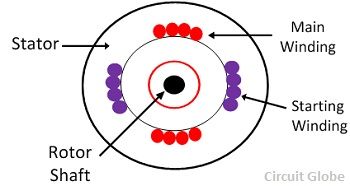

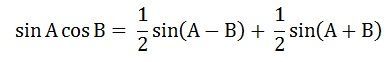

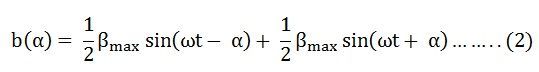

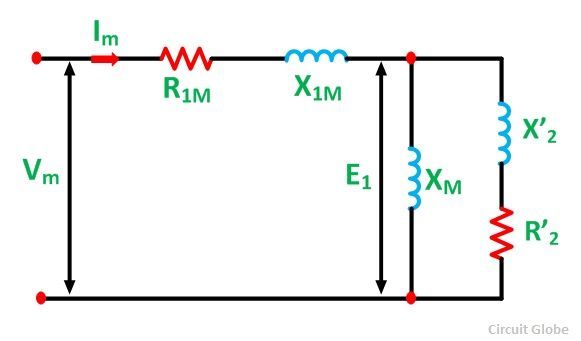

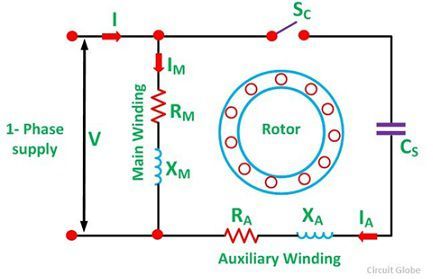

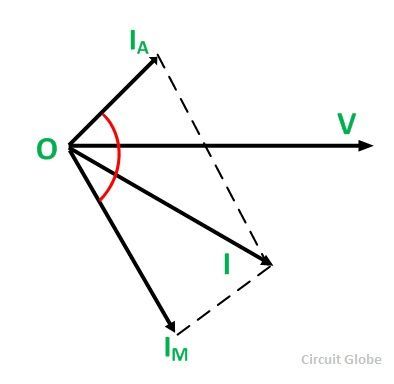

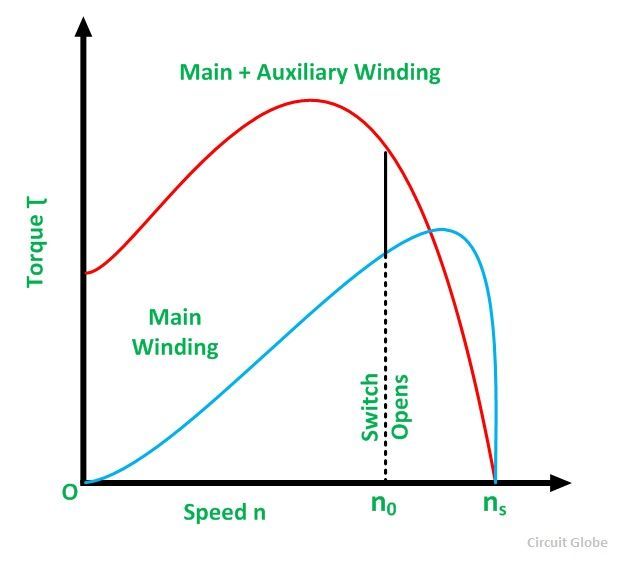

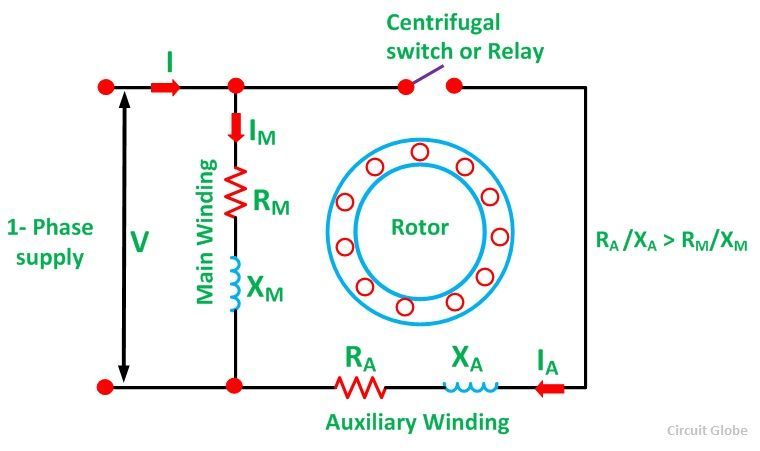

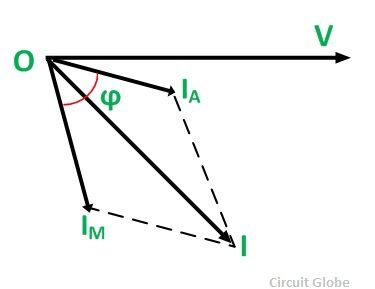

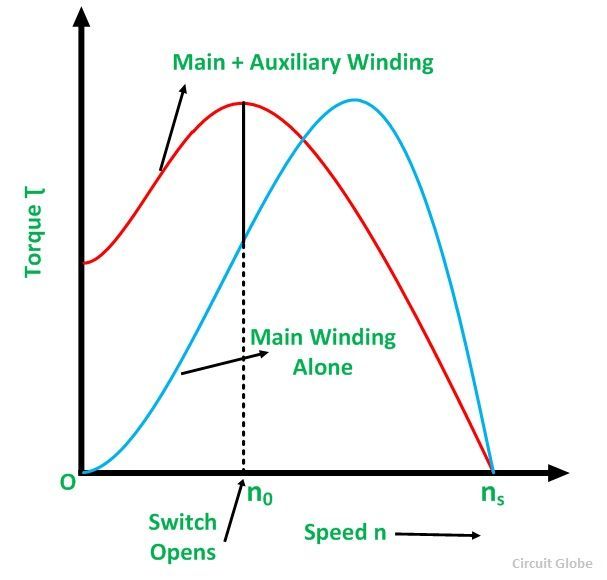

1. Three phase induction motors are self-starting whereas the single phase induction motor is not self-starting. This means the 1 –phase motor has no starting torque and hence it needs some auxiliary means to start at the initial stage.

2. The three Phase Induction motors have higher power factor and efficiency than that of a single phase induction motor.

- Size and Weight of alternator

The 3 Phase Alternator is small in size and light in weight as compared to a single phase alternator.

- Requirement of Copper and Aluminium

3 Phase system requires less copper and aluminium for the transmission system in comparison to a single phase transmission system.

- Frequency of Vibration

In 3 phase motor, the frequency of vibrations is less as compared to single phase motor because in single phase the power transferred is a function of current and varies constantly.

- Dependency

A single phase load can be efficiently fed by a 3 phase load or system, but 3 phase system cannot depend or feed by a single phase system.

- Torque

A uniform or constant torque is produced in a 3 phase system, whereas in a single phase system pulsating torque is produced.